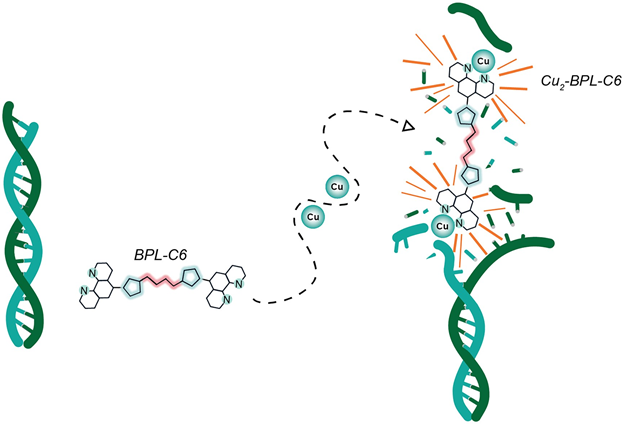

My name is Alex and I’m from Kilkenny. I graduated from University College Dublin with a BSc in Chemistry in 2017 and began my PhD under the supervision of Dr Eoghan McGarrigle. My research focusses on the development of new synthetic methodologies in organic synthesis, in particular using organosulfur chemistry. Following some initial studies in the area of asymmetric organocatalysis, I began developing a new, selective method for synthesising a relatively underexplored class of sulfonium salts – pyridylsulfonium salts. Having synthesised these new compounds, I proceeded to apply them in sulfur-mediated transition metal-free ligand coupling reactions, producing bipyridine and bis-heterocyclic products. Bipyridines and bis-heterocycles are prevalent motifs across a range of disciplines in chemistry. They are found in natural products and drug targets and they are frequently used as ligands for transition metals. Syntheses of these bis-heterocycles are predominantly transition metal-catalysed. Our new synthetic methodology offers an attractive alternative to transition metal-catalysed syntheses of these compounds.

I took up a placement in MSD Ballydine in January 2021 in the Process Development and Commercialisation (PDC) department, reporting to Tom O’Ceallaigh. During my placement I worked on a number of different projects. The main project I focussed on was supporting new product introduction. Together with my co-workers, I carried out the development work needed prior to the production campaign on a small scale in the lab, supporting the scale up of the process in the factory. This development work included aspects such as water spiking studies and filtration studies. I attended online weekly meetings with the R&D team in New Jersey throughout the duration of my placement, and had the opportunity to present my results at these meetings. This was a great experience to participate in the knowledge transfer needed to successfully scale-up a process from R&D to factory production across two different sites.

I carried out supporting experiments during factory production, providing valuable information about the process. I attended various meetings dealing with issues which arose during production and helped to carry out the lab work needed to address these issues. Other projects I worked on during my placement included carrying out the lab work to support deviation investigations in supply products. This gave me a good insight into the chemistry used to synthesise a number of products on site. I also participated in the making of a TY video for the MSD virtual TY experience, contributing about 30 minutes of video footage. This video included an introduction to the labs in MSD, a demonstration of how we run crystallisations in the lab and an introduction to biocatalysis. Overall the work I carried out was quite varied and I felt I had a well-rounded experience.

In some ways, the work I was doing was familiar to me – in both my PhD and on placement my day-to-day activities involve organic synthesis in the lab, carrying out reactions using various chemicals. The scale of the reactions I was carrying out was very different, increasing from milligram quantities in my PhD to reactions up to 100 grams on placement. The equipment used in my placement was mostly new to me, with good exposure to new technologies such as OptiMax and EasyMax reactors, and the Blaze laser imaging technology. Although I was still synthesising small molecules, there was a lot of practical learning taken from doing things on a much bigger scale. I also learned a lot more about crystallisation, something I hadn’t had much detailed exposure to in my PhD. I’ve taken away a lot of ideas for how I could improve my own research and I have a much deeper understanding of how crystallisation works after my time on placement.

A big difference for me when I was on placement was the amount of people working on the same project. In my main project on placement, for the one-step it took to make the product there was a team of about 15 people in Ballydine and about 20 in New Jersey. This meant that there was a lot of cross-functional meetings as well as lab work. In my PhD, I work on a project with one other person and the majority of time is spent in the lab. The people involved on placement also came from very diverse backgrounds, bringing understanding from other perspectives such as engineering and quality. It was a great opportunity to broaden my knowledge and to try to understand the roles of the various departments contributing to making the drug. Another difference was that in my PhD, I do a huge variety of reactions making a number of different products: on placement I was largely working on the one chemical step, but there was a much deeper understanding of this step and the factors which influenced how the product was made.

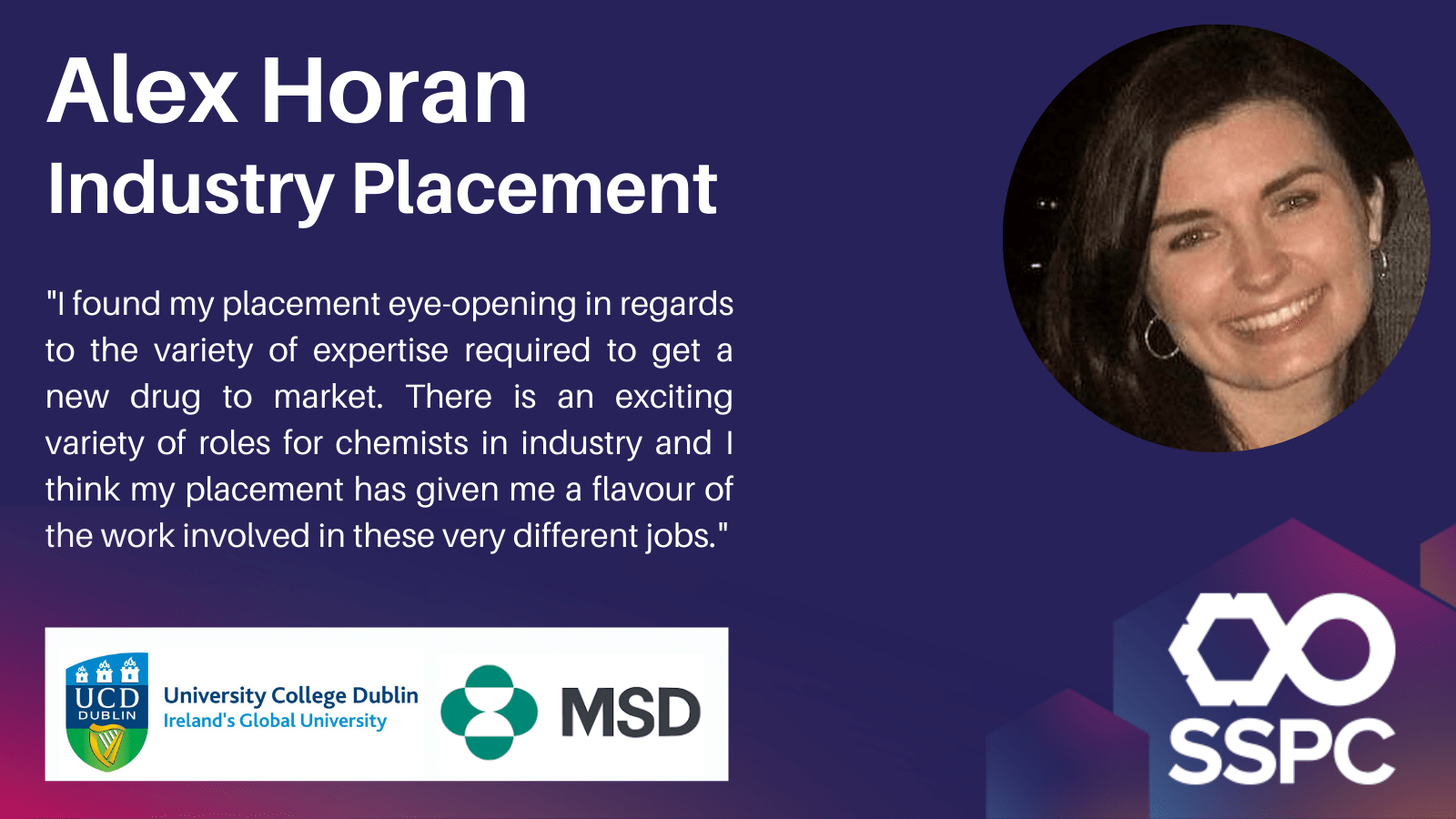

Overall, my PhD has set me up well to understand the chemistry that is carried out in the pahrmaceutical industry, but there is much to learn about the practicality of carrying this chemistry out on a large scale. I found my placement eye-opening in regards to the variety of expertise required to get a new drug to market. There is an exciting variety of roles for chemists in industry and I think my placement has given me a flavour of the work involved in these very different jobs. Chemistry on an industrial scale requires a lot of new learning and is a different type of challenge to academic research.

Before beginning my placement, I was sure that I wanted to pursue a career in the pharmaceutical industry following my PhD, and this placement has further reinforced that. In particular, I have found the area of new product introduction to be very exciting and I am looking forward to starting out in a similar role after my PhD. The placement has given me a great opportunity to witness the types of roles I could be doing even further down the line. I have some idea of what I could be working towards, for example I’d love the chance to manage a new product introduction. The variety of roles in industry is particularly appealing – there’s always something new to learn and the work is rarely boring.

An industrial placement is an invaluable experience for a PhD researcher. It’s essentially a long interview where you can demonstrate what you’re capable of to a company you might want to work for in the future. The opportunity to trial a role without having to commit to a long contract is rare and a placement offers you this. You are exposed to a variety of roles and really it’s the first time you get to explore the activities involved in different positions and test out where your strengths might lie. You also get to meet alot of new people from various backgrounds who can share their experiences with you. Connecting with a company is a huge advantage when it comes to searching for a job – you have experience your peers may not have had, and if you have performed well on your placement, then you will likely be welcomed back if positions are available.

On top of this, I think that taking a few months out to do a placement has been beneficial to my PhD. I am returning to my research project refreshed and with new perspective. Having worked in a different environment for four months, I think there are learnings and new ideas I can take and implement in my PhD.

“Alex came to work with us at the start of Jan 2021, when the country was in level 5 Covid restrictions. She demonstrated great resilience and ability to adapt to new ways of working on site. She quickly learnt how to use new technologies and use them for experiments, which facilitated scale up of a new process. Alex demonstrated her strong technical capability when working on process challenges and discussing her results with experienced researchers. Alex within a short time became a very valued member of the new product team with her do attitude and her positiveness will be missed.”

Tom O’Ceallaigh – Director in Process Development and Commercialisation at MSD Ballydine