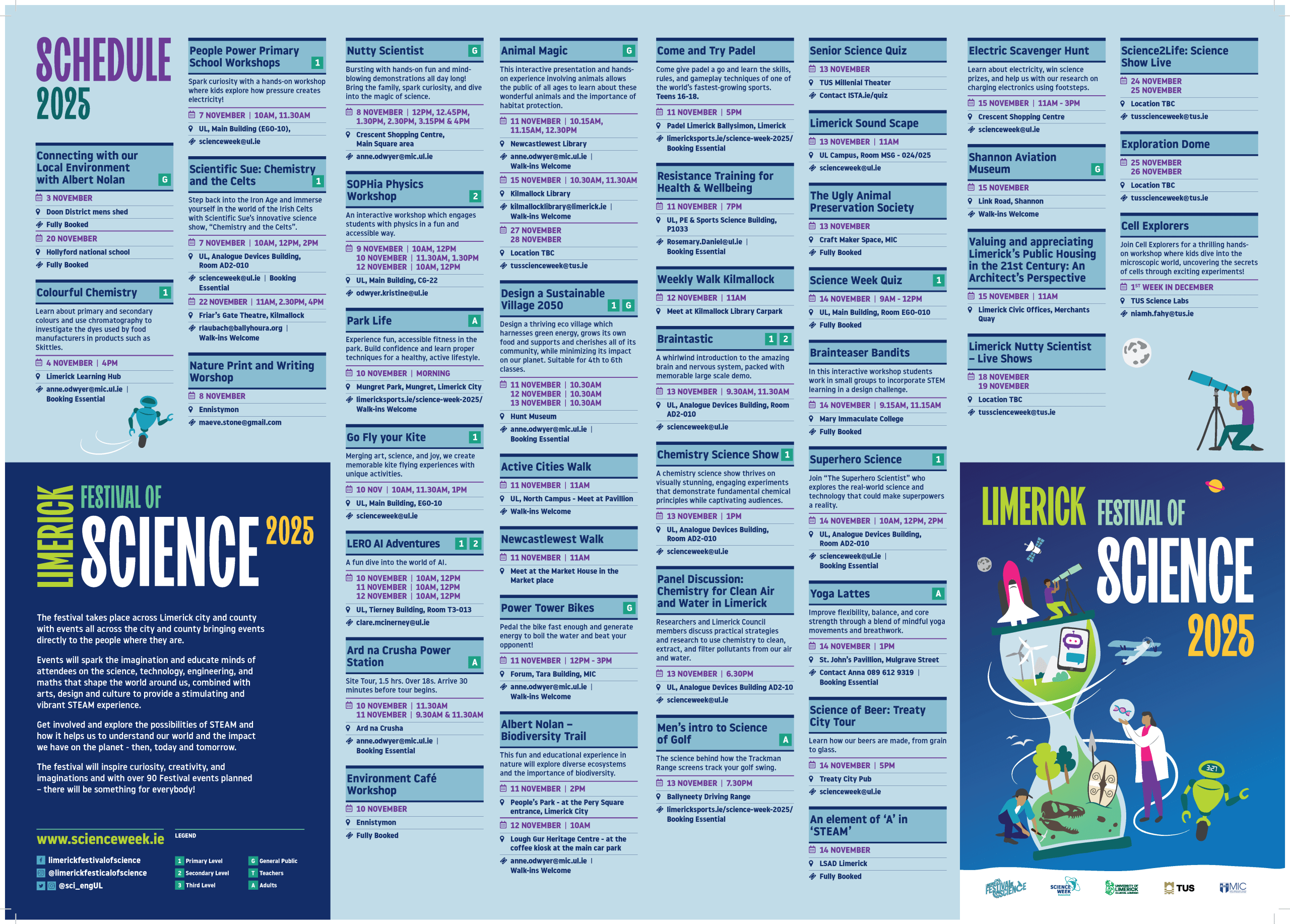

Pictured at the launch of the Phase II Resin project, at the BioPharma Chemical Ireland (BPCI) conference were standing, Aisling Arthur, SSPC Industry Engagement Manager, Prof. Sarah Hudson, (seated), Matt Moran, Director, BPCI, Dr Sarah Hayes, SSPC COO, Prof. Damien Thompson, SSPC Director and Prof. Philip Nolan, Director General, Science Foundation Ireland (seated). Picture: Conor McCabe.

SPC, the Science Foundation Ireland (SFI) Research Centre for Pharmaceuticals, at the University of Limerick has launched phase two of a partnership with leading industry partners to address the growth in the protein A resin market.

The collaboration sees five leading biopharma companies Pfizer, Eli Lilly, Janssen, BMS and MSD working together to address challenges that are shared across the biopharmaceutical manufacturing sector. These include the rising need for early diagnosis of chronic diseases, the growing demand for drugs in the development of vaccines and therapeutics (specifically proteins called antibodies), and an increase in R&D investments in pharmaceutical companies.

The 18 month project has the potential to revolutionize the way we think about antibody-based products and their applications. Many antibody based drugs are used for cancer, arthritis and chronic diseases. Biopharmaceutical industries are currently reluctant to adopt resin reuse procedures, despite the enormous cost saving it could introduce. This research could massively support industry partners and their endeavours to bring down their costs and the cost of medicines.

This collaborative project under the direction of SSPC Principal Investigator Professor Sarah Hudson is using state of the art research instrumentation to explore the possibility and feasibility of reusing resins, making the production of antibody medicines, more cost effective and environmentally friendly. It is also intended that the research outputs from this project will contribute to building confidence, and challenge current regulatory thinking around the multi-product reuse of resins in specific circumstances with the potential to reduce waste, maintain standards, and minimise costs in pharmaceutical processes.

Without clear regulation on the practice of reusing protein A resins with different antibody products and without the option to reuse this substance, this process is expensive and produces a lot of waste.

Professor Sarah Hudson said:

“Progressing to phase two in this project holds great promise for the future of the industry. This project focuses on developing and refining resin-based materials and processes, with the aim of creating more durable and sustainable products. The future implications of this project are promising. Overall, the progress made in phase one of the SSPC resin project holds tremendous potential for transforming various industries by providing them with more robust and sustainable material solutions.”

Research into protein A resin multi-use could have a significant impact on society, providing numerous benefits, such as health and environmental sustainability. In terms of human capacity building, this project is upskilling researchers and facilitating knowledge transfer to industry in the technical, quality assurance and economical aspects of downstream biopharma processing.

Attending the launch at IDA headquarters, Prof. Philip Nolan, Director General (SFI), said:

“I am delighted to be at the launch of the second phase of this ground-breaking project. It demonstrates the commitment of SSPC to driving innovation and research within the pharmaceutical industry. This reciprocal sharing of information, approaches and new knowledge generated ensures that the impact of this work will be enhanced and have global significance for the sector.”

Theresa Ahern, Senior Advisor, Manufacturing Science and Technology Eli Lilly, Kinsale, Cork, said:

“The significance of the contribution of this project in implementing multi-product Protein A re-use for clinical manufacture cannot be underestimated. Whilst the regulatory authorities understand the problem faced by the bioprocessing industry in the under-utilisation of resins, it takes a comprehensive process and analytical data package to make a compelling technical case for the re-use of resin. The successful delivery of the data package through this industry and SSPC project collaboration, coupled with the integration with the larger BioPhorum group means that a risk-based, data-driven industry guideline will be published for the implementation of multi-product Protein A re-use”.

Donna Hamilton, Global change Facilitator, BioPhorum, said

“BioPhorum partners with organizations and academia to enable it to deliver its mission to provide an environment where the global biopharmaceutical and medical device industries can collaborate to accelerate their rate of progress, for the benefit of all. Working with the University of Limerick, this collaboration is focused on harnessing the use of experimental data to save resources and ultimately money, through the reuse of Protein A resin across multiple products within a clinical manufacturing environment. BioPhorum’s Protein A Resin Reuse team, in partnership with UL, aims to use its data to support a proposition paper that will shape the current industry and provide a justification for Protein A resin reuse, which could ultimately lead to an estimated annual saving of $8 million per site”.

Dr Sarah Hayes, COO, SSPC added:

“The rising need for early diagnosis of chronic diseases, coupled with growing demand for drugs, specifically antibodies, is largely responsible for the growth of the Protein A resin market. This has led to a global shortage of Protein A resin. This work is extremely significant, as it brings together industry, academia and colleagues in BioPhorum via the SSPC, building on our track record of collaboration. This reciprocal sharing of information, approaches and new knowledge generated ensures that the impact of this work will be enhanced and have global significance for the sector.”