Simin Arshi, University of Limerick is this year’s winner of SSPC’S Industrial PhD Placement Award. Simin’s was placed at MSD, Ballydine. She worked as a chemist in the Process Development and Commercialisation (PDC) department.

Read Simin’s account of her placement…..

I did my industry placement in MSD Company Ballydine, one of the premier research- intensive biopharmaceutical companies working on developing essential medicines and vaccines. I worked as a chemist in the Process Development and Commercialisation (PDC) department. I was involved in a project on the development of Ladiratuzumab vedotin, an effective medicine for the treatment of different types of cancers.

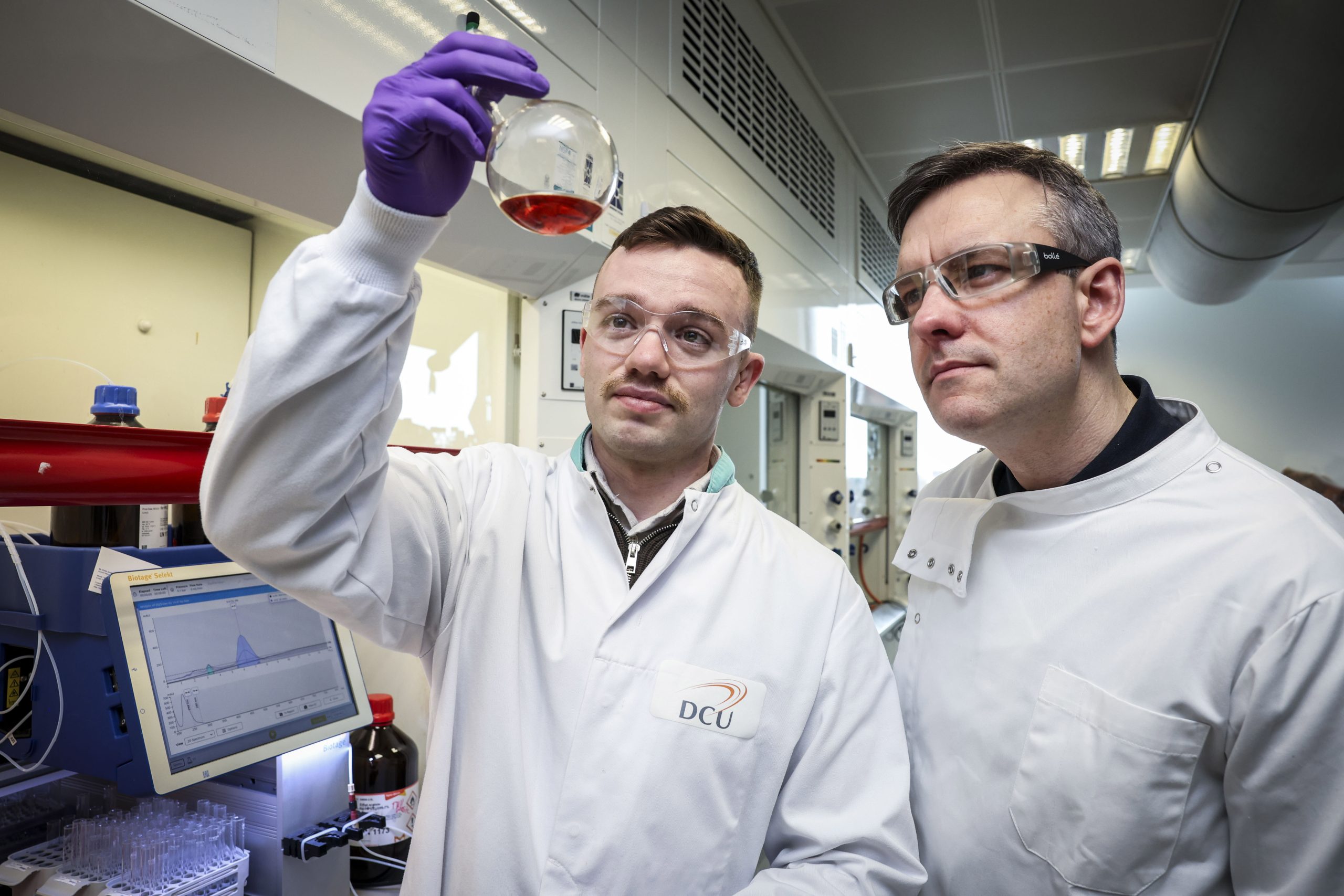

There was an effort to simulate large-scale setups such as filtration, distillation, and crystallization on a small scale by using the small size of setups used in the factory. Therefore the result of experiments on a small scale will be the same as those on a large scale. The synthesis step involved several catalytic reactions catalyzed by enzymes or organic catalysts in the batch reactor, with intermediates formed at each reaction step. At the end, the best method of disposing of the reaction solution was proposed. The reactor cleaning procedure was another critical step in the project. Washing and cleaning vessels on a small scale is relatively simple and can be performed manually. Manual cleaning and washing are impossible with large-scale reactors with dimensions of up to a few meters. Therefore, it is of importance to find a cleaning procedure using different solvents. The best solvents for cleaning were chosen visually by flowing different solvents into the dirty vessel.

At MSD, I had the chance to visit a manufacturing site to observe a large-scale manufacturing process, which was a great experience. I could see the flow and batch reactors on a large scale which was interesting since my Ph.D. project is based on flow reactors.

Working in MSD gave me a good insight into how an immobilization method can be scaled up in the factory and what kind of surfaces or matrixes should be used for enzyme immobilization. Before industry placement, I was using electrochemical methods for enzyme immobilization on the conductive surfaces. However, by understanding the scale-up procedure, I discovered that using electricity and conductive surfaces on a large scale is not cost-effective. Handling and transferring huge conductive surfaces for immobilization and keeping them in a cold and humid storage is challenging. Moreover, enzymes are only attached to the surface, so a lower quantity of enzymes on the surface makes this method uneconomical.

Therefore, I started focusing on some materials, such as agarose beads. Metal-free Agarose beads are specially designed for large-scale protein immobilization. These materials are easy to handle on a large scale. Agarose is a typical strongly hydrophilic, lyophilic, and highly inert colloid in water. It is a porous gel that absorbs water, making it a suitable environment for enzymes. It possesses a unique hydrophilic nature, being ideal for enzyme immobilization and increasing the storage stability of the immobilized enzyme. Doing experiments on a small scale might be fast, but it takes a very long time for a large scale. For example, filtration on a small scale may take 30 min, but it may take a couple of hours on a large scale. Therefore, considering all differences between large and small scales, the enzyme should have high catalytic stability at room temperature. Agarose beads provide a suitable environment for enzymes to maintain their activity for an extended period. Therefore, I have been immobilizing different enzymes, such as Lactate dehydrogenase (LDH) and chloroperoxidase (CPO), in agarose to be used in the enzymatic reactions. Enzyme immobilization takes only 3 hours, and immobilized enzymes showed excellent storage stability for up to a few weeks. This immobilization method is suitable for scaling up in the industry.